In the sophisticated world of modern product design, mechanical and electrical engineers often face a shared challenge: fitting complex, high-performance electronics into compact, irregularly shaped enclosures. Standard, flat circuit boards can be rigid and unforgiving, forcing product designers to compromise on form factor. This challenge has pushed designers to work closely with their chosen pcb manufacturer to develop innovative solutions, with flex-rigid PCBs emerging as one of the most powerful. This hybrid technology elegantly solves the puzzle of three-dimensional packaging by seamlessly integrating rigid and flexible circuits into a single, unified component.

A flex-rigid PCB is exactly what its name implies—a circuit board that combines the stability and component-mounting capability of a rigid board with the pliable, dynamic nature of a flexible circuit. It offers the best of both worlds, enabling engineers to design electronics that can bend, fold, and fit precisely where they are needed, all while eliminating the traditional points of failure associated with cables and connectors.

The Anatomy of a Flex-Rigid PCB

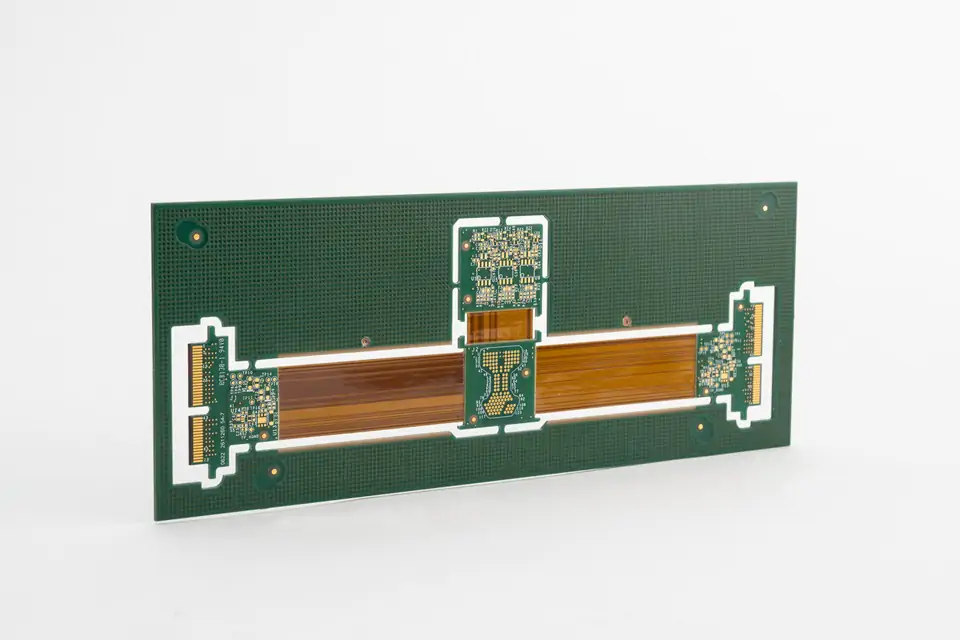

Understanding the construction of a flex-rigid board reveals its inherent advantages. It is a cohesive unit composed of two distinct parts:

- Rigid Sections: These areas are constructed from standard, robust PCB materials like FR-4. They serve as the stable mounting platforms for the majority of the components, such as microprocessors, connectors, and high-pin-count devices, providing the necessary mechanical support.

- Flexible Sections: These integrated “flex tails” are made from durable, pliable materials like Polyimide. They act as built-in, multi-layered cables that connect the rigid sections. The traces are etched directly onto the flexible substrate, ensuring a seamless .

These sections are laminated together during the manufacturing process to create a single, durable board. There are no solder joints, wires, or connectors linking the rigid and flexible parts—the connection is an intrinsic part of the board itself.

The Advantages: Why Choose a Flex-Rigid Design?

While the initial cost of a flex-rigid board may be higher than a conventional PCB and cable assembly, its total cost of ownership and profound design benefits often make it the superior choice.

- Unmatched Design Freedom & Space Savings: This is the primary driver for adoption. Flex-rigid boards can be bent and folded to conform to the contours of a product’s casing. This allows designers to utilize every cubic millimeter of space, enabling smaller, lighter, and more ergonomically advanced products.

- Superior Reliability and Durability: By eliminating connectors, ribbon cables, and the associated solder joints between separate boards, you remove the most common sources of mechanical and electrical failure. This drastic increase in reliability is why flex-rigid technology is standard in mission-critical applications where failure is not an option. The inherent flexibility also provides exceptional resistance to shock and vibration.

- Reduced Assembly Time and Cost: A flex-rigid design simplifies the assembly process significantly. It reduces component count by eliminating the need for cables and connectors, and it cuts down on manual labor, leading to faster assembly times and a lower risk of human error.

- Improved Electrical Performance: The seamless transitions between the rigid and flex areas allow for controlled impedance and shorter, more direct signal paths. This enhances signal integrity, which is crucial for high-speed and high-frequency applications.

Key Applications: Where Reliability and Form Factor are Paramount

Flex-rigid PCBs are indispensable in industries where space, weight, and reliability are critical design drivers. In Israel’s advanced technology sector and globally, you will find them in:

- Aerospace & Defense: Avionics systems packed into the tight confines of aircraft, missile guidance systems, and ruggedized battlefield communication devices.

- Medical Technology: Life-critical devices like pacemakers and defibrillators, flexible endoscopes, surgical tools, and compact wearable patient monitors.

- Industrial Controls: Robotics and automated machinery that require durable interconnects to withstand constant, dynamic movement.

- High-End Consumer Electronics: Drones, high-end digital cameras, and foldable smartphones where form factor and durability are key selling points.

In conclusion, flex-rigid PCBs are more than just a circuit board—they are a sophisticated electromechanical solution. By merging the electrical path and mechanical connection into one, they empower engineers to overcome complex packaging challenges, enhance product reliability, and push the boundaries of innovative design.