In the high-stakes world of 5G telecommunications and defense electronics, a quiet revolution is reshaping how organizations procure critical RF over Fiber infrastructure. While industry giants continue to offer standardized, rigid product lines with lengthy customization cycles, a new breed of agile vendors is emerging to fill the gap between off-the-shelf limitations and fully bespoke engineering costs. At the forefront of this transformation stands RFOptic, a company that has pioneered what industry insiders are calling the “customized off-the-shelf” approach—delivering tailored solutions with the speed of standard products and the precision of custom engineering.

The Procurement Dilemma Facing Modern Engineers

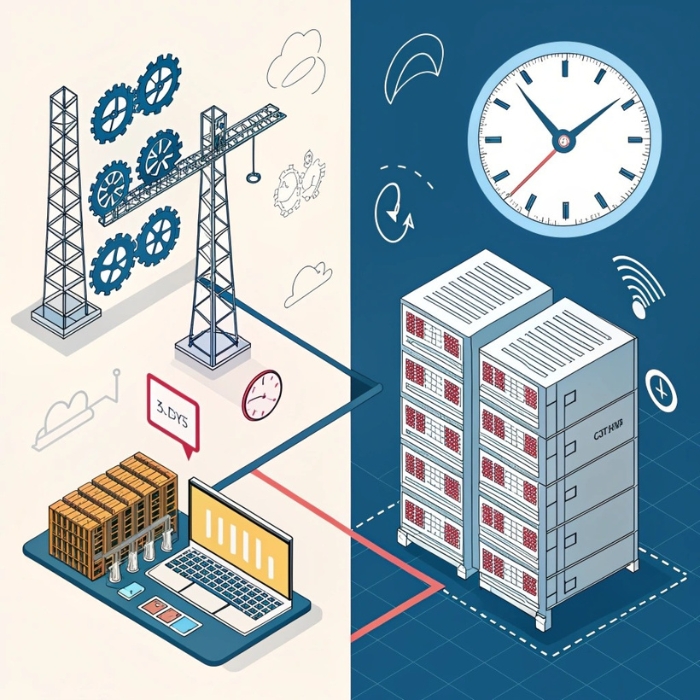

Engineers working on cutting-edge 5G deployments and defense systems consistently face an uncomfortable dilemma. On one hand, standard commercial off-the-shelf (COTS) equipment offers predictable pricing, proven reliability, and immediate availability—but rarely matches the exact specifications their applications demand. On the other hand, fully bespoke engineering solutions deliver precisely what is needed but come with astronomical costs, extended development timelines measured in months or even years, and the technical risks inherent in any ground-up development.

This dilemma has real consequences. Projects get delayed while engineers wait for custom solutions. Budgets balloon when standard equipment requires extensive workarounds or supplementary systems. Compromises in performance specifications cascade into suboptimal system-level outcomes. In the fast-moving 5G market, where time-to-deployment directly impacts competitive positioning, and in defense applications where performance can be mission-critical, neither option is truly acceptable.

The Hybrid Solution: RFOptic’s Market-Leading Approach

RFOptic has built its market leadership on recognizing and solving this fundamental procurement challenge. The company’s approach combines the best attributes of both worlds: proven, production-ready hardware platforms that can be rapidly configured, modified, and optimized for specific customer requirements. This “customized off-the-shelf” model enables delivery of tailored solutions in weeks rather than the months required by traditional custom development—and at a fraction of the cost.

The foundation of this capability lies in RFOptic’s modular product architecture. Products like the company’s Programmable RFoF links and High Spurious-Free Dynamic Range (HSFDR) modules are designed from the ground up with customization in mind. Built-in flexibility at the hardware level—combined with software-configurable parameters accessible through USB, SNMP, HTML, and REST interfaces—enables rapid adaptation to diverse requirements without starting from scratch.

From Standard Hardware to Tailored Solutions

The customization options RFOptic offers span the full range of system parameters that matter to engineers. Frequency range optimization ensures that products precisely cover required bands rather than paying for unnecessary spectrum coverage. Gain profiles can be adjusted through built-in controlled Low Noise Amplifiers and step attenuators. Enclosure modifications accommodate specific form factors, environmental requirements, or integration constraints. Connector configurations match existing infrastructure. Firmware customization enables unique monitoring, control, or automation requirements.

This flexibility extends across RFOptic’s entire product portfolio. Whether the application requires a compact 3GHz module for GPS distribution, a wideband 18GHz system for 5G testing, or a High SFDR solution extending to 40GHz or beyond for satellite communications and electronic warfare, the same customization philosophy applies. The result is that customers receive exactly what they need, precisely specified for their application, without the traditional penalties of custom development.

Why Agility Beats Scale in RF Over Fiber

The advantages of RFOptic’s agile approach become clearer when contrasted with how larger competitors operate. Major corporations offering RF over Fiber solutions typically optimize their operations for volume production of standardized products. Their engineering resources focus on next-generation product development rather than one-off modifications. Their manufacturing processes are tuned for efficiency at scale, not flexibility for customization. Their sales channels are designed to move standard SKUs, not to engage deeply with unique customer requirements.

These structural factors mean that even when large vendors offer customization, the process is slow, expensive, and often requires minimum order quantities that make sense for their economics but not for the customer’s. A request for a modified frequency range or alternative enclosure might take months to quote, more months to develop, and come with pricing that reflects the disruption to standard processes rather than the actual engineering effort involved.

RFOptic’s organizational structure is fundamentally different. With two decades of specialized focus on RF over Fiber and Optical Delay Line solutions, the company has built teams, processes, and infrastructure specifically designed to handle customization efficiently. Engineering expertise is immediately accessible to customers. Manufacturing operations accommodate variation as a normal part of workflow rather than an exception. The result is turnaround times measured in weeks and pricing that reflects actual costs rather than organizational friction.

Real-World Impact: Rapid Prototyping Saves Projects

The value of RFOptic’s agile customization capability is demonstrated repeatedly in customer engagements. Consider a scenario typical in 5G testing environments: a Fortune 500 telecommunications company needs to deploy a new test configuration supporting frequencies and channel configurations not addressed by any standard product. Traditional procurement paths would require either compromising on test coverage or waiting months for custom development.

RFOptic’s approach transforms this scenario. Starting with proven Programmable RFoF platforms, the company’s engineers work directly with the customer to define exact requirements. Modified firmware addresses specific frequency coverage. Adjusted gain staging optimizes performance for the target signal levels. Custom enclosure options enable integration into the existing test facility infrastructure. The complete solution ships in weeks, enabling the project to proceed on schedule.

Similar stories play out in defense applications, where RFOptic has established a long track record of supplying governmental institutes and defense system integrators. Electronic warfare applications often require phase-matched multi-channel configurations with specifications that vary by platform and mission. Radar testing applications need Optical Delay Lines with precise delay values matched to specific system parameters. In each case, the ability to rapidly adapt proven technology to specific requirements delivers value that standard products simply cannot match.

Bridging Commercial and Defense Requirements

One of RFOptic’s most significant technological achievements is bridging the traditionally separate worlds of commercial telecommunications and defense electronics. The company’s product portfolio spans from 6GHz solutions serving commercial 5G applications to 40GHz and beyond for defense and satellite communications—all built on consistent architecture and customization capabilities.

This breadth enables unique cross-pollination of capabilities. Technologies developed for demanding defense applications—including ruggedization, extended temperature operation, and high dynamic range performance—become available to commercial customers requiring enhanced reliability. Conversely, the volume-driven cost optimization of commercial products benefits defense customers who need proven technology without unlimited budgets. RFOptic’s position spanning both markets uniquely enables this technology transfer.

The Future of RF Procurement

The “customized off-the-shelf” approach pioneered by RFOptic represents more than a competitive strategy—it points toward the future of RF equipment procurement. As 5G networks evolve toward 6G, as defense systems incorporate increasingly sophisticated electronic warfare capabilities, and as satellite communications expand through LEO constellations, the demand for precisely specified RF over Fiber solutions will only grow.

Organizations that recognize the limitations of both pure COTS and fully bespoke approaches are increasingly seeking the middle path that RFOptic has mastered. The company’s continuing investment in modular platforms, flexible manufacturing capabilities, and accessible engineering expertise positions it to capture this growing demand. For customers, the message is clear: the days of choosing between “not quite right” and “too expensive and too slow” are ending. The customized off-the-shelf revolution is here.

Frequently Asked Questions (FAQ)

Q: What does “customized off-the-shelf” mean in the context of RF over Fiber?

A: Customized off-the-shelf refers to the approach of starting with proven, production-ready hardware platforms and rapidly adapting them to specific customer requirements. This contrasts with standard COTS (fixed specifications) and fully bespoke development (ground-up custom engineering). RFOptic’s approach delivers tailored solutions in weeks rather than months at a fraction of custom development costs.

Q: What types of customization can RFOptic provide?

A: RFOptic offers customization across multiple parameters including frequency range optimization, gain profile adjustment through built-in LNAs and attenuators, enclosure modifications for form factor and environmental requirements, connector configurations, and firmware customization for unique monitoring and control requirements.

Q: How quickly can RFOptic deliver customized solutions?

A: RFOptic’s modular product architecture and specialized manufacturing processes enable delivery of customized solutions in weeks rather than the months typically required for traditional custom development. Exact timelines depend on the scope of customization required.

Q: What frequency ranges does RFOptic’s customization capability cover?

A: RFOptic’s customization capabilities span their entire product portfolio, from sub-6GHz commercial applications through 40GHz and beyond for defense and satellite communications. This includes standard RFoF modules, High SFDR series, and Optical Delay Lines across all frequency bands.

Q: Why can’t larger vendors offer the same customization flexibility?

A: Large corporations typically optimize operations for volume production of standardized products. Their engineering resources, manufacturing processes, and sales channels are designed for efficiency at scale rather than customization flexibility. Structural factors make customization slow, expensive, and often subject to minimum order quantities that don’t align with customer needs.

Q: How does RFOptic serve both commercial and defense markets?

A: RFOptic’s product portfolio spans from commercial 5G applications to demanding defense requirements, all built on consistent architecture. This enables technology transfer between markets—defense-grade reliability for commercial customers and volume-optimized pricing for defense applications—creating unique value across both sectors.